Kingston Developments have just been accredited with ISO 9001:2000 certification for internal Quality Management system

Kingston continue commitment to BASDA. For many years now Kingston Developments have been an active member of BASDA.

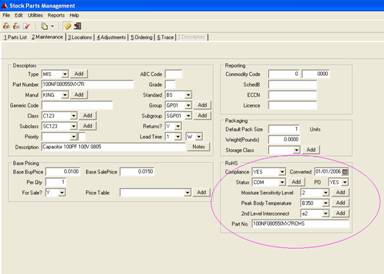

RoHS Compliance

This upgrade feature to KBS provides a means for recording and managing stock which is either RoHS compliant, not compliant, or its status is unknown. It enables the identification and tagging of products containing hazardous product at part number and at batch levels.

Parts may be tagged and RoHS details recorded such as RoHS status and compliance, peak body temperature, moisture sensitivity level, second level interconnect, terminal finish and material, compliance date. A separate RoHS part number may be recorded if required.

Customer records may be flagged and Kingston’s allocation routines will ensure that stock shipments are directed correctly. Customers who must be only be supplied with compliant stock can be identified and KBS will ensure that only stock marked as compliant is allocated to their sales orders. With regards to Purchasing, stock that must be compliant is identified on the Purchase Order document using automatic standard text and RoHS partnumbers if applicable. All stock movements are recorded in the Trace screen. Stock labelling and documentation will also facilitate stock control according to the terms of the directive.

BENEFITS

- The system provides control over the organisation involved in the directive

- Reduces manual effort in organising compliance of parts and suppliers

- Helps deliver excellent customer service

- Detailed reporting for management control

- Full batch traceability for audit purposes

Screen Shot